Thursday, July 31, 2025

More Vacation Stuff.

Wednesday, July 30, 2025

The Project X Reveal.

[I suspect ICE to have impacted the two flower sellers at the cemetery. I try to visit the XYL's grave every Friday and bring fresh flowers. I purchase the flowers at a roadside stand near the cemetery entrance, where the price is excellent, and the selection is unique.

The two YL's who support the stand are sisters and have mentioned they are there "every day". Since I was away last Friday, I made my makeup visit yesterday and will be back again this coming Friday. The YL's are in place at 8AM. They were not there yesterday, and the time was 9AM. Since the town is Oxnard and the favorite fishing hole of ICE... we can surmise what happened! The XYL got a visit but no flowers.]

The beauty of my sojourn to Denver was to help clear my brain fog. With that clarity I can only say to myself what were you thinking.

The Project X radio is a Transcom SBT3. It was a short-lived product and only about 500 were made and sold. Two hundred were sold to the Philippine government and the rest sold to hams.

Tuesday, July 29, 2025

Where I went on my summer vacation? I went to Denver!

Nothing like a family vacation with son #3 to clear the head. Son, Nicolas and I had an amazing week's adventure visiting in an around Denver and Chyenne, Wyoming.

N6QW at the Argo Gold mine.

Monday, July 21, 2025

Taking a Break!

I have been consumed by Project X and I need to take a break. The stark realization is that this rig even when 100% was likely chewing gum and bailing wire.

Sunday, July 20, 2025

Yet Another Mystery on Project X.

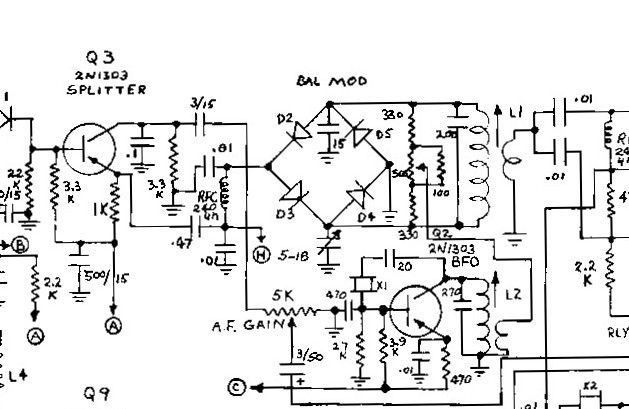

Before investing a huge time sink in building / reworking the FP-200 power supply for Project X, I wanted to assure myself that everything short of the Final Amp is working!

Saturday, July 19, 2025

Done in by Technology!

Most but not all SSB Transceivers have RF Amplifier Stages. This stage can be troublesome as it is a high wire balancing act to provide a sufficient amount of gain but not so much that the atmospheric nose amplification is so great as to negate the gain stage.

Friday, July 18, 2025

Well, the VFO rebuild did not work!

After putting all back together, the VFO was inoperative. But now it is working, and the fix will astound you or should I say the implementation will give you cause to say," I'll be damned!"

Common Failure Mechanisms

Tin Whisker Growth Tiny conductive filaments called tin whiskers can grow inside the transistor casing, especially if the interior is tin-coated. These whiskers can cause internal shorts between the transistor terminals, leading to erratic behavior or complete failure.

Internal Shorting Some vintage germanium transistors—especially those with built-in substrate grounds—are known to suffer from internal shorting over time. This is often due to poor sealing or contamination during manufacturing.

Thermal Sensitivity Germanium is more sensitive to temperature fluctuations than silicon. Heat stress or rapid thermal cycling can degrade the junctions, especially if the substrate ground doesn’t provide adequate thermal dissipation.

Voltage Spikes & Breakdown Without proper input/output protection, transient voltage spikes can damage the base-emitter junction. Substrate-grounded designs may lack sufficient isolation, making them more vulnerable to such stress.

Aging & Shelf Life Many germanium transistors are decades old. Even unused ones can degrade due to oxidation, moisture ingress, or breakdown of internal seals. Substrate-grounded types are particularly susceptible if the grounding path allows leakage currents or corrosion.

Thursday, July 17, 2025

I would have never guessed.

Finally Access to the VFO Board!

In looking at the schematic and measuring voltage at the emitter we had power to the circuit but no oscillation. The 1st thought was that the Germanium transistor was bad... I pulled it only to find it tested good. Plugging it into a socket on a working homebrew rig (Plessey Circuit) it was good!

Now that I had access to the components I could make other voltage measurements. I noted there was voltage on the collector BUT none at the junction of RFC and 5.6K and the .01 Cap. An ohmmeter measurement across the RFC (shocking) it was open. Ah hah, found it!

Not so fast McGee! True it was open, further checks once removed from the circuit affirmed that. But there was no visible sign of an open, it was not crisped nor any leads broken off. It was just plain open.

Seeing the choke was inaccessible, there was no probing of or any accidental damage to the choke before it died. It just stopped working. The transistor is good so no huge current surge that would have smoked the choke. I must not rule out the Malocchi!

The replacement choke is a 1000 microhenry (AKA 1 Millihenry) and unfortunately, you have to reassemble everything to test if the repair worked.

The rig designer never thought DFMA or that any rig maintenance would ever be required. I did get a chance to use my Krud Kleaner on the chassis and the Project X front panel. It worked well.

Hopefully I will get it tested today and see if I really did find the problem. A real help to me was I started off by writing down what had to be done and the sequence of steps. I also followed the script as I did the task! RTFM!

Tasks and Sequence!

I stopped last night just short of powering on the rig as I was tired and was concerned about getting this far and making a boo, boo. That also gave me time to rethink anything that I had not covered in the work tasks and the fix. I will start by retracing what I did and verify, no shorts or solder bridges.

At this stage, I am glad I decided to fix the VFO as I learned a few things along the way. If the choke replacement is not the cure, then that still is good info. We know the device is good so that reduces the set of what is the problem.

Someone was diddling with the dial drive mechanism which I fixed. The main tuning knob consists of a National Velvet Vernier reduction drive that is panel mounted. At the end of the vernier shaft are two discs one is fixed and the other spring loaded like a pressure plate. A large diameter disc is fitted to the shaft of the VFO tuning capacitor and this larger disc rides between the two discs that are spring loaded. In effect the ratio of the two smaller disc radius and the radius of the disc on the VFO capacitor is s further reduction.

My seat of the pants calculation suggests with the two drives it is like a 50:1 reduction. Translated 50 turns of the tuning knob to complete tuning across the band. The Swan Monobanders and the SBE-33 used this small/large disc to tune the across the band. But these rigs did not have the added vernier drive.

When disassembling the VFO cap I found that the large disc was not riding between the two smaller discs but on the outside of the first disc. Much smoother tuning now! I had to use a long screwdriver to pry open the two discs as I slid the VFO cap disc into position. I spotted this even before I did any disassembly as I noted at times some backlash in tuning.

Them that know can make things go.

It's been 6 months now so how would you answer the question are you better off today? The super rich are counting their crypto so we have their answer. Are your grocery prices better and is your bank account growing?

73's

Pete N6QW

Wednesday, July 16, 2025

Reversing course on Project X.

First a caution and a funny story. I hate the type of Manhattan construction where you use Super glue to glue the cut off copper squares to a PC Board. Frankly Super glue and Pete are a volatile combination. Somehow every time I use the product, I get my fingers stuck together.

Tuesday, July 15, 2025

Design Decisions ~ The process.

Raspberry Sundae

State of the Union (SOTU)

How does one reconcile what will be said today at the SOTU when compared to the reality of our check books. I am now paying significantly m...

-

Cruise through the lower part of the ham bands bands and what do you hear? Well, FT-8 and CW. Often you will not hear any SSB stations yet g...

-

Shown below is the Block Diagram for the 20M PNP SSB Transceiver steered in the Transmit Mode . The components shown in the dotted block ar...

-

What a great day to Binge on Chocolate and experience the pain of that filling that has been leaking. I would be in that category with the ...

.jpg)