#48 is Finished --- #49 in Work.

October 3, 2020 ~ uSDX NOW Working!

This morning I touched up the solder joints on the encoder and the switches. Boom now working on receive!

BUT THIS IS WHERE I WAS LATE YESTERDAY. Still food for thought about the encoder, switches and display...

I received the missing parts installed same including the new firmware and #49 is best described as a crystal set with only 5 feet of wire attached! I have three ATMEGA 328 microcontrollers that have the very latest firmware installed and the condition is exactly the same with any of the controllers in the radio. I do get some of the functionality so I know the code has been loaded on the 328's.

My belief is that there is a hardware issue other than the 328 quite possibly in the encoder and the push button switches. Here is the issue --the radio does not respond to the command inputs. This is a menu operated radio and it is difficult to get the radio to respond to command inputs. There have been some guides published on how to navigate the menus -- but this radio is much like a small child who ignores instructions and inputs (Maybe like our emperor. See wearing a mask is important!). See the guide below the photo.

Turn the encoder and nothing changes on the display; but going through some other button pushing you realize the frequency has changed as a new value will show up but you hear nothing. It did work once and I heard a 40M station quite well -- but never again did it work. This lends a weight of evidence to some hardware issue.

Others have their uSDX perking right along -- but alas mine is a like a lump of coal that has not been ignited -- no warmth, no light, no glow. I think I will just move away from it for a period of time as I am fresh out of ideas.

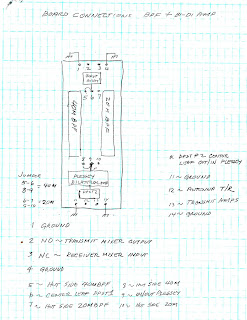

Here are a couple of things I would do different knowing what I know now. I would (like I saw in one set of constructor photos) dump the cheap detent encoder and the flimsy push buttons and hardwire in a better encoder and switches mounted on a panel. I would also remote the display on that same panel. With the display as a plug in the board -- hard to view. I am not so much interested in a compact radio as I am one that works and has decent hardware.

Yes Virginia, this is the early stages of a uSDX build. I was shorted some parts by Digi-Key and so had to order from Mouser. Thus I am not done! I also need to build the LPF's and have parts coming for those too.

The build is pretty simple but you have to know some stuff to do this stuff. Example, there are twelve 100nF caps to be installed. I looked over the board and found all 12 locations. While I was doing the hunting, I wrote down on a my construction notes the twelve part ID's like C1, C13. Then as I installed the part, double checking the silk screen with the value, I marked it off the listing. Once I got through the list I checked all twelve were marked off and double verified that I indeed installed the right part value at the right location.

There was a problem with Spurs which has been resolved by Guido PE1NNZ and new Firmware is available for download It is V1.021.

The only thing aside from not having all of the parts yet being able to run the ATMEGA 328 is the crazy menu's. On boot up there are 9 sections with sub menu's in those section such as MODE (USB default, LSB,CW) or Band (40M default). The problem I have been having it seems a mystery once in the section --how to make changes. You essentially have four controls. The encoder which has two -- the encoder tuning and the PB control and then there are two Momentary PB switches. At times I have been able to change bands or change modes but no idea how I did it. The four controls interact but not intuitive what they do. This was designed by a software guy! Have pity on us hardware freaks! Must be a fault on my part as I don't own and ICOM 7300 thus not used to menu stuff.

There is an issue with the ATMEGA 328 purchased from Digi-Key. It is as dumb as a rock as it lacks the Boot Loader. So you have to Jimmy a way to get a Boot Loader installed and then you can load code. You can either do it with two UNO's hay-wired together or go to Amazon and purchase a USB asp with 6 pin ICSP Adapter. This gizmo connects to your computer and then. connects to an UNO where you have installed the bare 328. Under the Tools Tab in the IDE are select a programmer (USBasp) and then hit Burn Boot Loader. Once you get the Boot Loader installed then you can install the new Guido Hot Fix Firmware.

An alternative is that All Electronics (out here in CA) sells the 328 with the Boot Loader installed --about $5. The USB asp programmer cost $20 with shipping.

The new Firmware if you are not using the QSX as the starting device must have the 1st Line nulled out like //#define QCX 1 . The display will now read uSDX on the 1st line

If you are using a stock Si5351 breakout board that has the 25 MHz clock then about line 899 there are three clock selections and choose the following. Null out the other two.

#define F_XTAL 25004000 //25MHz SI5351 crystal

I am sharing more than I really know; but the kit went together fairly quickly -- one full day if you take your time and follow an orderly process. Oh look carefully at the board to see "tough" installs. I started with installing all of the capacitors and there are five electrolytic types. One of those a 10 UFd. sits right in front of a special 5 VDC LDO regulator which is surface mount.

INSTALL the REGULATOR before the cap otherwise you will burn the cap with the soldering iron as you try to solder the three tabs. Another suggestion do not install the sockets and other hardware parts (switches, jacks, power) until all of the passives (resistor, capacitors, diodes, crystals) are installed.

I used some aluminum pillars one the board so that when you turned the board over to solder the parts the board was elevated off the work surface. My process is to insert the part into the board and then use masking tape to hold it in place and next turn over the board to solder at the underside. An 80 watt Radio Shack soldering iron with a 3/4 inch tip is inappropriate for this Fine work.

Oh Forget that ROHS solder as you will end up with bad connections and cold solder joints --get the 60/40 type solder and wear a mask.

Ergonomics will be an issue for me with my FFS (Fat Finger Syndrome). The encoder looks cheap and it is doubtful it will last more than about 10K rotations. The BNC connector is at the bottom of the board so packaging WILL BE an issue.

So for me if I were to build a 2nd unit I would create a top panel where I will install a robust (smoother -- and not a detent type) encoder, and locate the BNC elsewhere. Better PB would also be on the list.

It would be easy to build an extension cable for the LCD. For the uBitx I bought some 4 inch long M/F jumper cables and simply did a pin for pin plug in and was able to mount the Raduino LCD on the front panel.

So #49 is in work and I won't have any news until all of the parts arrive.

73's

Pete N6QW

10/1/2020

Yesterday on Unit #48, I added the back chassis plate and fitted the panel with the Power Cord, Linear Amp Switching Jack and the Antenna Connector.

You might wonder how I can crank out rigs at a lightning fast pace. It is all about the tools you have PLUS thinking creatively. You just can't go out and buy stuff like one used to do. Pre-Covid19, I made a once a week stop at Home Depot and simply toured the aisles looking for stuff that co 1uld be used in projects.

Today, not being able to simply run through Home Depot has forced me to look in the bins and boxes at stuff I already have. Boom, I have been surprised at all the stuff I have in the past ordered and simply squirreled away for future use. The future is here now!

Speaking of tools, there are CNC machines on the market in the $300 to $500 range that do an absolutely creditable job in making electronic hardware. Whether it is making circuit boards or cutting rectangular holes in panels, it can be done by you. You don't have to be a machinist or have special shop skills --just read the manual and use that computer between your ears.

Unit #48 was easily built using the CNC and some good old fashioned creativity. Take for instance the IRF510 which needs a heat sink. Here is what I did for a heat sink, There is a piece of double sided copper board about 1.5 inches by 1 inches that is the circuit board and heat sink. On the back side I removed the copper over an area about 2X the size of the IRF510. But left the rest intact.

Next using an insulating mica thermal pad and a nylon shoulder washer I formed a mounting kit so that the shoulder washer was on the underside of the board. The shoulder rests in the PC Board itself so that the mounting bolt never comes in electrical contact with the grounded PC Board

A 3/4 inch 6-32 bolt was passed through the washer, through the PC Board, through the Mica insulator, through the IRF510, through solder lug (this connects the Drain) and finally a 6-32 nut. When this is cinched up the IRF510 is in thermal contact (I did use thermal grease too) with the copper board; but electrically isolated. Next I have four 1/2 inch aluminum pillars that are threaded for 2-56 bolts that connect to the PC board and to another L Shaped aluminum sub-chassis which houses the two main stacked transceiver circuit boards.

Thus there is a 1/2 inch air-gap between the IRF510 board and the L Shaped bracket. BUT through the four aluminum pillars there is a thermal path for the heat to dissipate to the larger aluminum sub chassis. This has worked well! Bottom line --I was fresh out of TO-220 transistor insulating kits, had no more TO-220 heat sinks and was sort of placed in a position to come up with an alternative.

The original plan was to have the IRF-510 on the top transceiver board. Too close and feedback issues. This solution kept the IRF510 in close proximity but provided electrical isolation and shielding. All done with the CNC Mill and IUWIH.

The fabricating of Unit #48 has provided a sense of deep satisfaction as it was a challenge to use what was at hand and think out of the box. Regretfully, I have run out of Juliyellow paint as I really wanted to paint this rig a nice bright color -- no running over to Home Depot so used the Juliano Blue (Oasis Blue).

So notable points -- this has a homebrew crystal filter at 4.9152 MHz and is proof that I do know how to build crystal filters. It is also small which was an engineering challenge to fit all into a smaller foot print; but not as small as the Second Shirt Pocket Transceiver which you can see below.

73'sPete N6QW

The fabricating of Unit #48 has provided a sense of deep satisfaction as it was a challenge to use what was at hand and think out of the box. Regretfully, I have run out of Juliyellow paint as I really wanted to paint this rig a nice bright color -- no running over to Home Depot so used the Juliano Blue (Oasis Blue).

Updated Photos of the #48 ~ 9-29-2020

I have made a half dozen contacts just this afternoon including two DX contacts into South America. Got a High Quality Audio Presence report from a station in Florida. So once again the Plessey Amps (all three sets) and the homebrew Crystal Filter rule the airwaves.

Work remaining: installing the back plate and finalize the power wiring and antenna connections. This is a winner!

The next two photos were taken before I installed the TR relays and LPF board.

SSB Transceiver #48 ~ 20 Meters.

[ The repackaging continues...

For those who still might be members of QRPARCI and have QRP Quarterly publications going back to 2011 you would find I penned an article on a 20 Meter Shirt Pocket QRP SSB Transceiver.

I am no longer a member of QRPARCI nor get QQ so I am woefully unaware if any other innovative projects such as the Shirt Pocket Transceiver that are being published. I do know that one of my other projects was recently republished.

Regrettably I was not even notified that they were doing that. It seems like when you submit an Article to QQ they maintain they own it and as an author you have no rights of publication. Needless to say QQ will not be on the receiving end of any of my current or future work.

I actually built two of the transceivers and this project was the first one where you needed a really big shirt pocket. However V.2 was much smaller and likely could fit in a shirt pocket. There are youtube videos of this earlier variant still on the you tube. The one on the left is the larger version and the basis of this repair/restoration/upgrade. The smaller one is only 16 cubic inches -- 2x2X4

Both versions involved the use of the Plessey Bi-Lateral Amplifiers, a homebrew 4.9152 MHz four pole Crystal Filter and a novel Crystal Switched two range VXO. The larger one had a Rx RF AMP stage and the second one did not (that was a mistake).

In an attempt in early 2020 to fit an Arduino Nano/Si5351 and 1/2 size OLED display inside the metal case of V1, some wires got crossed and I smoked a lot of parts including the transmit amplifying stages and the receiver RF amp. So I just put it away mainly to not look at it; but to rethink the replacement electronics.

The basic receiver, filter, mic amp and audio stages were unscathed so I only needed to deal with the Rx RF Amp and the Transmit Stages. I made a board the same size as the basic board and used aluminum spacer to top mount the board. On that board is another Plessey bi-lateral amp stage (much like the two in the IF Module) only it serves at the Rx RF Amp and Tx Pre-driver.

Also on that board is the 2N2219 Tx Driver Board and the Bias Network for the IRF510. Initially I had the IRF510 installed there too. BUT too close and RF Feedback! I made a small auxiliary board and side mounted just that stage. Feedback gone!

The 2020 redo involves the Arduino Nano / Si5351and a Color TFT Display. The transmit chain has been simplified by using the bilateral Plessey stage and the receiver is as hot as ever. I get about 4 watts out and that will drive an outboard linear amp to 100 watts.

Smoking the parts was not good; but it was in that the upgrades and improvements are very nice and increases the functionality and overall operation of the rig.

Let's see your build.

73's

Pete N6QW

*******

The Atomic Pi $39.95 @ Amazon.

Regrettably I smoked at Raspberry Pi3. Well actually it works but the WiFi no longer does. So kind of useless where you need Internet Time like for WSPR and FT-8. So I needed to find a replacement.

That is when I spotted the Atomic Pi which is branded as a super competitor to the Raspberry Pi. It is sort of like Emperor Trump telling his cluster of supporters only he can fix things and lying in the process.

The Atomic Pi is an Intel Atom based Single Board Computer that started life as an embed for industrial applications. Somehow that got derailed and there were tens of thousands of these lying (good term) around a warehouse and that is where some genius figured a way to sell these boards as a Raspberry Pi Alternative. They price point is less than $40 and it has a 1.4 GHz processor that can run at 1.9 GHz, and 2GB of RAM. It has 16 GB of built in Storage but an SD Card Slot for up to 256 GB. HDMI output and a 1.5 Watt Stereo amplifier.

The Atomic Pi is being sold with a bottom mounted breakout board and even comes with a separate Camera. The OS installed is Unbuntu. But you can install Windows 10 (limited) via the SD Card.

You will need a 5 VDC at 4 amp Pig Tail supply that is fed via a terminal block on the breakout board. I have not been able to get Netflix to work (as yet) but I have installed Quisk and WSJTX. They sell a supply for about $10 -- a $50 bill will get you the Atomic Pi and the Power Source.

Some limitations --poor documentation, only two USB ports ( a 3.0 and a 2.0) kind of big and uses passwords for everything. There is a limited supply as no more are being built and once the warehouse is empty much like the Emperor: A lot of hype but no more in the store.

But it does get you a replacement for the RPi3 and puts you back on the air. Oh another Big Bonus --a Real Time Clock on board.

It does have WiFi but you need to buy one of those funny APEX antennas (about $6) . Scroll down for photos

In Case you haven't guessed by now #48 is now working. See the videos above... Never sleep as you will miss something important.