A shift from vacuum tubes to solid state also created a seismic change in how we built things. Some of us witnessed that change firsthand especially in things like a chassis and cases. Want sticker shock go look at Jeff Bezos website and search on aluminum chassis?

Certainly, some of that cost is in the metal as often the aluminum is from offshore. But another is the old supply and demand. Of course, one answer today for one aspect is the 3D printing of plastic cases but another may be this jewel.

An 18-Inch-Wide Metal Break~ Harbor Freight

My shop has one of these and today's price is about $45 but long ago this was only $27 when I bought it. Now you will need some things like large C Clamps and some short pieces of metal to bend small parts, but you can build a chassis or case using this very tool -- I did. Also, Home Depot sells galvanized metal flashing really cheap which is the source metal.

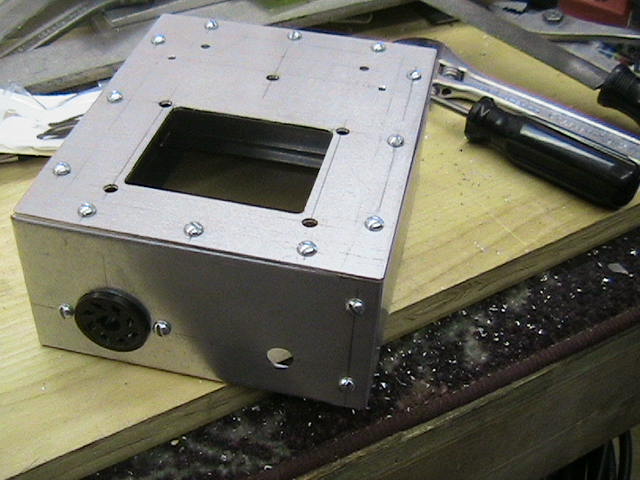

Now not everyone who home-brews will need a HV power supply but certainly this would work for a 12VDC supply. What may not be obvious but the whole chassis is only 3 pieces, two of which are bent up.

A couple of notes here include laying out the metal and locating the holes for the final assembly. All holes are drilled while the metal is flat and not bent.

The small metal pieces mentioned earlier are used as an auxiliary bending bar to make that small right-angle bend. The sequencing of the bending is also important, so you don't bend over stuff already bent.

The galvanized metal seems flimsy but when bent over and assembled is surprisingly solid. This has something to do with metal pieces in tension and compression. That power transformer weighs several pounds, and the metal does not buckle. The top plate is of course thicker and more rigid than the sides. It is solid from the get-go and contributes to transferring any loading to the sides.

The Transmitter portion of a Paraset.

The 350VDC supply was used with this Paraset transmitter. This chassis was a bit flimsy because the bottom is open and should have had a bent over lip. Yes, I was short on material and a bent over lip would also support a bottom cover. Next time...

So, a small investment from Harbor Freight yields a tool that can be used for making cases or a chassis.

Let me not fool you that just because you found another place to spend the plastic, it does take some knack to be able to pull off making a chassis or a case. You have to be able to visualize the final product and mentally sort out the bending sequence.

That is a skill not everyone has so now open up a browser, search Amazon and buy it now. But if you made it yourself you would have bragging rights -- even the chassis and case are homebrew! WYKSYCDS!

73's

Pete N6QW